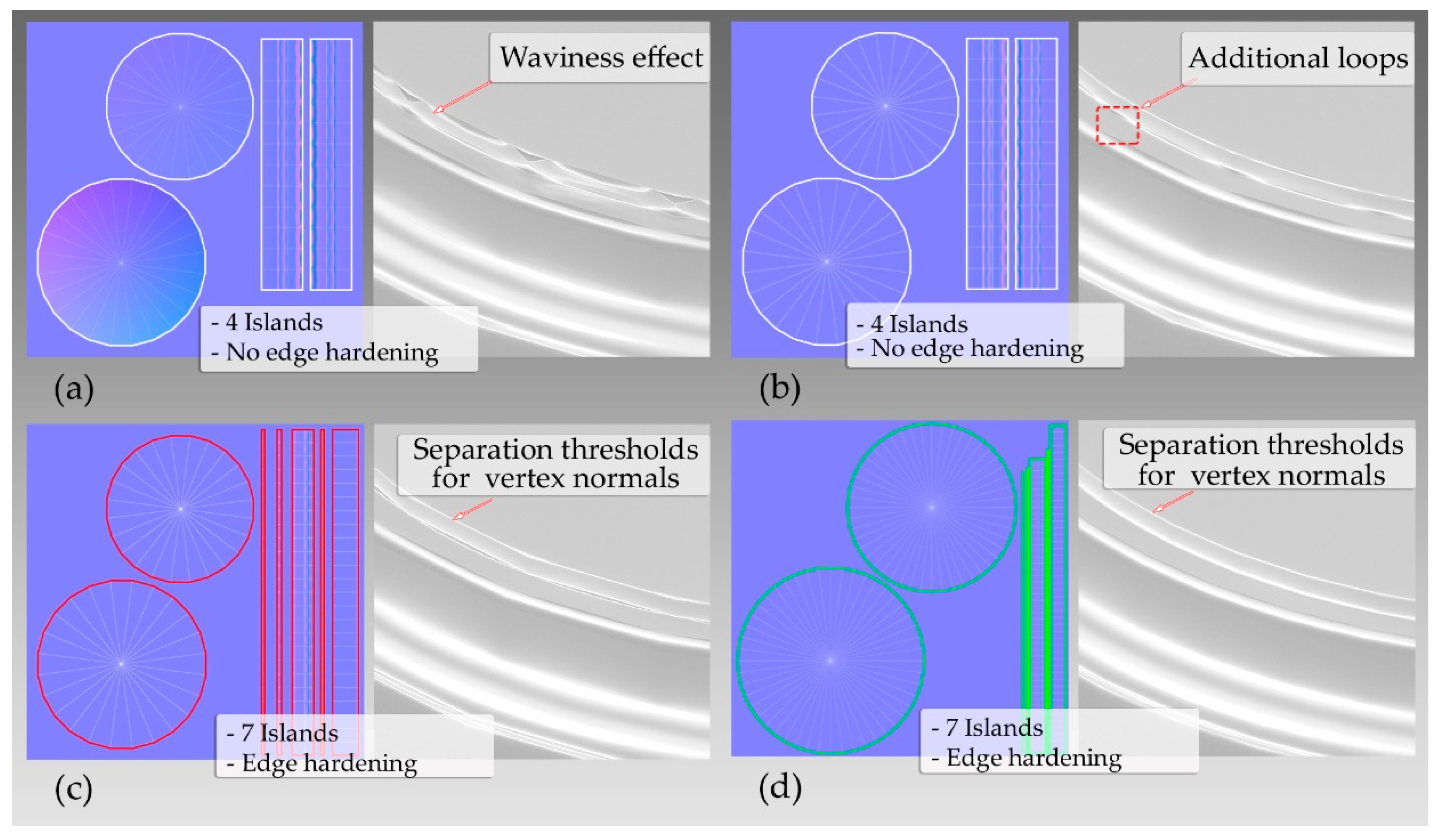

The reason is that this number refers to the actual pixels (dots) in the image of a scan, or the number of small “dots” of toner that is printed to make up the complete image. We talk about the resolution of our laser printer and scanner in “dots-per-inch” (which you would think is how we should talk about halftones). This number is called the “frequency” or “Lines-per-inch – LPI.” Yes, lines-per-inch doesn’t seem right but in the old camera days you would refer to the halftone screen “ruling” and this is where it came from. Halftone dots are referred to by a number based on the number of dots per linear inch. While this article is more about halftone dots, the problem of exposing and printing a small dot is still the same whether it is a halftone or random square dot. Index color separations are done using random square dots that are all the same size. Since halftone dots are not actually dots, but small ellipses, they have a definite pattern and angle to them (figure 2).ĭon’t confuse halftone dots with stochastic random dots (figure 3).

#Separation studio printing problems series#

The halftone process does not actually happen until you press the print button and the image is “rastorized” and a program called PostScript converts the gray areas into a series of dots. Images that have shading or tints of a color are made into a halftone as they are output to a printer. This is where the halftone comes in.Ī halftone is simply a group of large and small dots that when viewed at a distance, have the appearance of continuous shades of gray or color in an image. Since a photograph has various tones ranging from solid black all the way to solid white, a method has to be used whereby you can reproduce the photograph in these “continuous tones” and still print a “solid” area of ink. In screen printing and the general printing industry, the screen (or plate in lithography) is only capable of printing solid areas. Note: Click on images to see larger version.

#Separation studio printing problems how to#

I am sure that the other writers, seminar lecturers, and developers of separation software will agree that now that the separations are easy, teaching printers how to work with halftones is the next step. And with low priced color separation software and lots of Photoshop training articles, creating halftone separations isn’t that hard. Even though the average printer’s bread-and-butter is still “spot color”, printers want to do more photorealistic images on light and dark shirts. The post To Rip or Not To Rip appeared first on Ryonet Blog.Over the years a constant source of discuss is about halftone dots. Then just click print and you have halftones!Ĭheck out the video below to learn the easiest way to decide whether you should use a RIP in your design or not: We left the defaults under the Configure Halftone tab.Under Ink Setup, check the box for Multi-Black.Under the Configure Printer tab, select your printer under the Detected & Supported Printers drop-down menu.You can use AccuRip with Separation Studio, Illustrator, Corel or Photoshop. Now you have your halftones! Creating Halftones with AccuRip: We also left our Frequency at 45 lines/inch, angle at 22.5 degrees and shape at Round. That will make the Halftone Screen dialog box pop up.The Bitmap dialog box will pop up, we left our Output at 300 pixels/inch and Method Use at Halftone Screen, then click OK. Another dialog will pop up saying, “Discard color information? To control the conversion, use Image > Adjustments > Black & White.” Click Discard.

Flatten image before mode change?” Click Flatten. A dialog box will pop up saying, “Changing modes can affect the appearance of layers.Here’s how to turn a design into a bitmap using Adobe Photoshop:

Simple right? Below we outline how to accomplish halftones with each method: Creating Halftones with a Bitmap: With AccuRip you have more control over details, it will look clean, and you don’t have to manually set the greyscale. With a bitmap, you have less control and less detail with your print. Rip:īoth of these methods will give you halftones.

There are two ways to create halftones that will allow you to burn and screen print them properly: Bitmap vs. You don’t always need to use a RIP when printing halftones though.

That process, a “RIP,” is accomplished with Raster Image Processing (RIP) software. But halftones also require that make a few digital adjustments to your design before taking it to the press. Halftones will help to enhance your design’s detail and depth. However, if you have a detailed design with shading or realistic looking effects, then you will probably have to use halftones to achieve the look you want. A large flat area of one color printed the same way across. In other words, they are created without shading or tonality. Maybe the first question that comes to your mind is, “What’s a RIP?” Most screen print designs are one or two colors, or spot color. How to know when your design should go into a RIP program…

0 kommentar(er)

0 kommentar(er)